Insulation Supplies

Benefits of Insulation

REDUCE ENERGY BILLS

Ceiling insulation batts can help reduce heating and cooling costs by up to 45%.

REDUCE NOISE

Acoustic insulation batts help to minimise noise transfer between different rooms.

SAVE ENERGY

Insulation helps to reduce energy usage, making your home more sustainable.

IMPROVE COMFORT

Thermal insulation helps to regulate the indoor temperatures of your home.

DIY PROJECT

Home insulation is quick and easy to install with the help of our DIY tips and videos

Visit Our Online Store

Best Selling Insulation products

While Stock Lasts

Online Specials

Half Price Insulation

Melbourne’s Premier Online Insulation Supplier

Explore our extensive selection of wall, underfloor, subfloor, and ceiling batts, conveniently organized by use, type, material, and brand. Rest assured, our team is also available to assist with insulation installation.

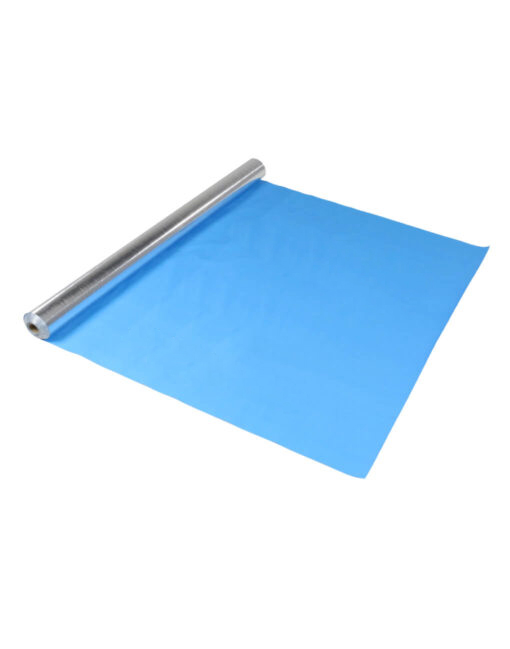

We cater to homeowners, builders, and developers in Melbourne, as well as various regional areas of Victoria. Our online store offers highly competitive prices for home insulation, ensuring affordability for our customers. Halfprice Insulation is the largest insulation online supplier in Australia dedicated to providing residential and commercial insulation solutions. Our range of reputable brands includes Knauf Earthwool Insulation, Ecowool. Bradford Insulation, Kingspan, PIR, Foilboard and James Hardie. You can choose from a variety of insulation types, such as glasswool, foil, polyester and foam.

Simply Give Us A Call !

Top-Tier Wholesale Insulation Supplier in Melbourne

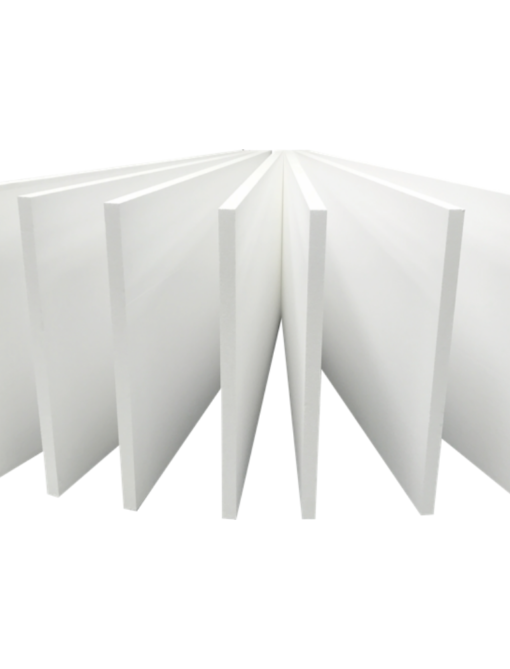

Welcome to Half Price Insulation, the leading supplier of premium-quality insulation in Melbourne. We pride ourselves in offering a wide range of insulation batts to meet all your needs. Our goal is to provide you with end-to-end solutions for insulating your home, ensuring that you receive the best products and services available. Whether you require ceiling insulation, wall insulation, underfloor insulation, we have you covered. Additionally, we offer fire protection, subfloor insulation, and acoustic wall insulation options.

Here at Half Price Insulation, we are committed to delivering excellence in both our products and services. Our team of experts is ready to guide and advise you on achieving effective home insulation in Melbourne and throughout Victoria, Australia.

Insulation for Australian Houses

If you are in need of high-quality insulation, we encourage you to reach out to our experienced team. You can explore our website to discover our extensive range of products and even use our insulation calculator to determine the exact amount you need for efficient insulation. We also offer the option of a site visit by our experts, should you require further assistance.

Rest assured, we are here to provide you with the expert guidance and advice you need for your insulation requirements. Contact us today to receive a free, no-obligation quote.

Reviews from Our Satisfied Customers

Our Story About Half Price Insulation

Cheapest Insulation Prices

Come discuss your project with us today!

Frequently Asked Questions

What are the factors I need to consider when selecting insulation batts?

A variety of factors influence your choice of insulation batts, including the climate in your region, the area you want to insulate, and your budget. The experts at Half Price Insulation can assist you in making a good decision.

What are insulation batts, and how do they work?

Insulation batts are like thick blankets for your home. They’re made of materials like fiberglass or rock wool and help keep your indoor temperature steady. By reducing heat transfer, they make your place more comfortable and can lower the need for heating or cooling.

What advantages do insulation batts bring to a building?

Installing quality insulation is a wise investment for your home. Melbourne’s leading suppliers, specializing in Earthwool Insulation, prioritize environmental consciousness. By reducing heating bills up to 50%, cutting carbon footprint, and ensuring a comfortable, quiet living space, insulation adds substantial value. With acoustic insulation for noise reduction and a 50+ years warranty, it not only enhances comfort but also contributes to long-term savings and the overall sustainability of your home.

Can I install insulation batts myself, or should I hire a professional?

Although installing insulation batts can be a DIY project, it is crucial to adhere to manufacturer instructions and safety guidelines. Incorrect installation may compromise effectiveness and pose safety risks. Many homeowners choose professional installation to guarantee proper placement and maximize the benefits of insulation.

Are insulation batts eco-friendly?

Several insulation batts are environmentally friendly, made from recycled materials or recyclable. Moreover, the energy savings they provide can help decrease greenhouse gas emissions, making them a sustainable option.